Product Solutions

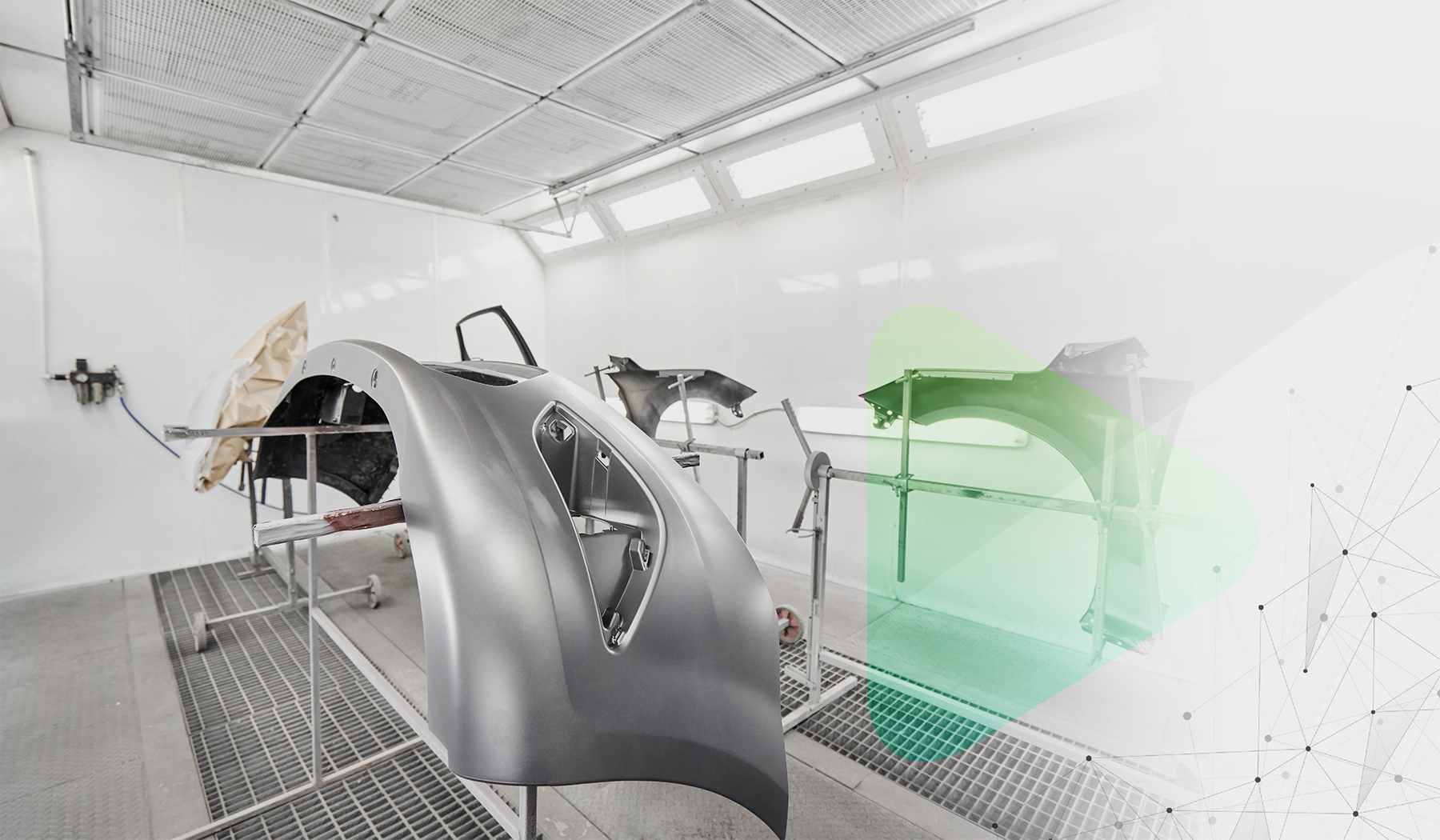

THE RIGHT PRODUCT & PROCESS IS KEY TO A SUSTAINABLE REPAIR

Implementing the right PROCESSES with the right PRODUCTS is key to a profitable and energy reduced repair process. By optimising your processes and using the right products, you can also streamline your operations and maximise your throughput.

Only by knowing your high energy sources, you can implement products and processes that will substantially cut your energy costs and carbon emissions.

We can support you in finding your right process throughout the whole repair process – just contact your local representative for more information.

SUSTAINABLE PREPARATION PROCESSES

Sustainable preparation of new panels, repair parts and spot repairs involves adopting environmentally friendly practices throughout the whole process using energy-saving primers and efficient curing methods.

DRYING PROCESS - AIR DRY AND MULTI-BAKE

A COOL CURE FOR HOT ENERGY BILLS

UHS Extra Clear 0396 is a fast drying clearcoat with an optional quick Air Dry Cycle that can be applied in a single visit offering repairers both a significant amount of energy saving and process time improvement, without compromising on performance.

Requiring only 20 min low baking at 40˚C, or being dust free after 20 min, this new clear enables more repairs and significant energy savings – all in one visit.

Air-drying clearcoat that significantly reduce energy consumption by up to 65%, through the removal of traditional oven-cured coatings.