Repair Parts

PREPARATION OF REPAIR PARTS

AIR DRY PRIMER

Multi-Dry Primer has been developed using the most advanced technology to provide MaxMeyer customers with a new Premium Air Dry Primer that helps reduce total repair process times and increase bodyshop efficiency.

It is easy to apply with excellent sanding properties whilst focusing on the efficiency of the bodyshop. The one visit application helps in reducing the overall process time and the fast air-drying makes this product environmentally sustainable.

Air-drying primer that significantly reduce carbon emissions by up to 40%, through the removal of traditional oven-cured coatings.

- FAST AIR-DRYING | ONE VISIT APPLICATION

- DRYING MODES: AIR-DRY, IR, BAKE

- ACRYLIC TECHNOLOGY

- Primer REACH Compliant: No CMRs in SDS section 2 and 3

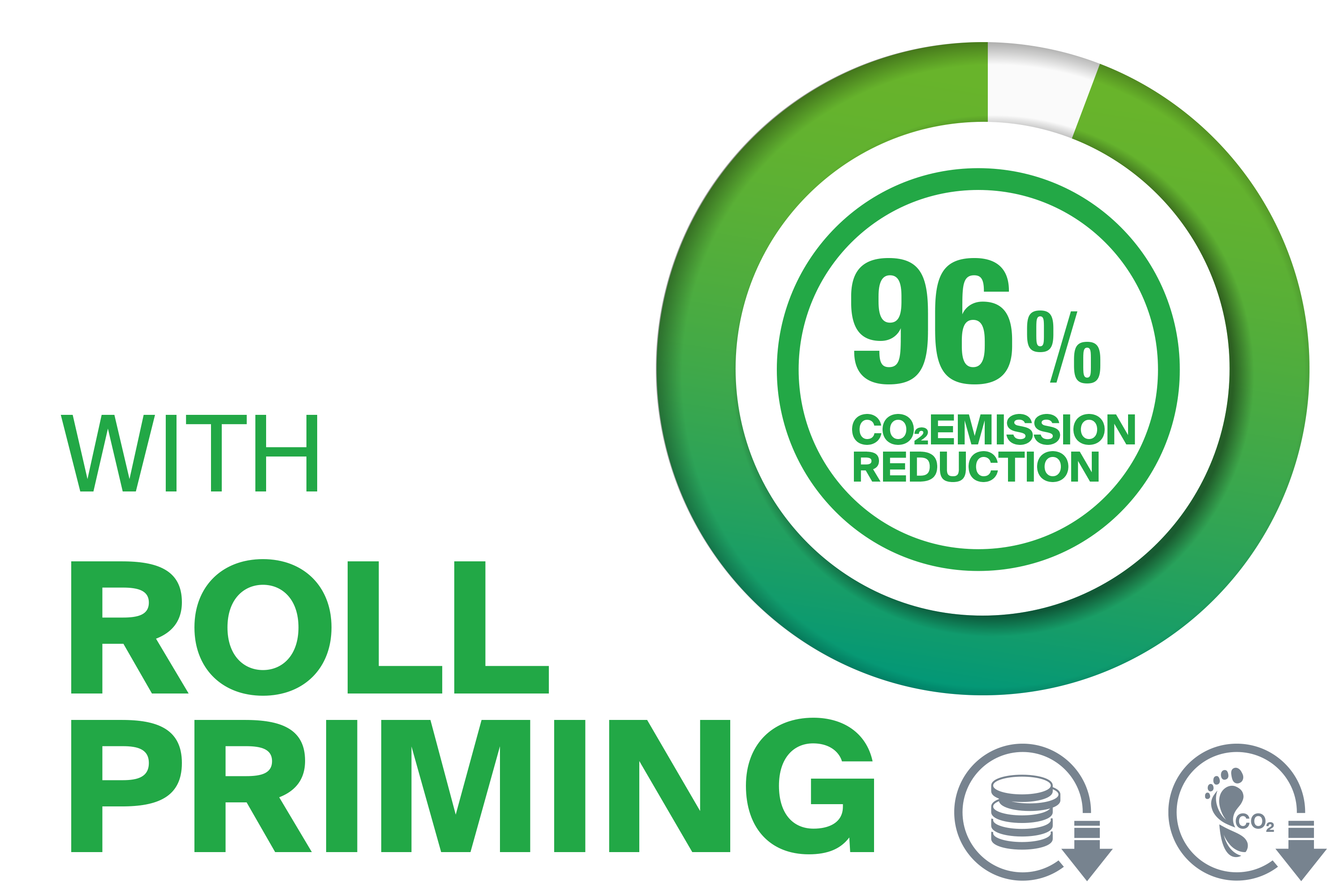

ROLL PRIMING PROCESS

SAVE SUBSTANTIALLY ON YOUR ENERGY BILLS

The roll priming process means that the primer application can take place outside the booth. No additional energy is needed.

On top of this, there is also no need to mask. So by using a roll primer process you can easily save ALL of the energy that would have been used applying a sprayable primer. This delivers the greatest energy saving to a bodyshop. Roll priming is the simple, yet effective, process of applying primer with a roller as opposed to a conventional spray gun within a booth. With many regions now focused on reducing energy consumption for the long term, thanks to MaxMeyer, roll primer has once again claimed its place in the workshop.

Roll primer, the application of primer via a roller, that offers energy savings of up to 96%* when replacing the application of primer with a spray gun in a spray booth.

- Applied outside the spray booth

- No mask material needed

- Multi-Dry Primer compatible for roll priming

*carbon reduction depends on how energy is produced and provided